Exploring TG Tubes: A Comprehensive Guide to Their Benefits, Uses, and Innovations

Introduction

In recent times, the term “TG tubes” has gained popularity across multiple industries, symbolizing excellence, resilience, and innovative design. These tubes are increasingly utilized in diverse sectors, including construction, manufacturing, and healthcare. This comprehensive guide explores the nature of TG tubes, their extensive applications, benefits, and the latest technological advancements that are influencing their development. Whether you’re a professional in the field or just curious about this adaptable product, this article aims to equip you with a detailed understanding of TG tubes.

An Overview of TG Tubes

TG tubes, commonly referred to as tubular goods, are engineered from high-quality materials such as steel, aluminum, or plastic. Their design features a tubular form that promotes efficient flow and enhanced structural strength, making them invaluable in applications that demand these characteristics. The adaptability of TG tubes enables their use across a diverse range of industries, including plumbing, automotive, aerospace, and more.

Manufacturing Process of TG Tubes

The creation of TG tubes involves multiple stages, beginning with the careful selection of materials tailored to the intended application. The chosen high-strength materials ensure that the finished products adhere to stringent performance standards. The meticulous manufacturing process is one of the key factors contributing to the popularity of TG tubes among professionals in various sectors.

Applications of TG Tubes

Construction and Infrastructure

In the realm of construction, TG tubes are essential components for structural frameworks, scaffolding, and support systems. Their lightweight design facilitates easy handling, thereby reducing labor costs and accelerating project timelines.

Automotive Industry

Within the automotive sector, TG tubes serve multiple purposes, including use in exhaust systems, chassis, and fuel lines. Their capacity to endure high temperatures and pressures makes them a reliable choice, significantly enhancing vehicle safety and performance.

Medical Applications

The medical industry utilizes TG tubes due to their reliability and versatility. These tubes are integral to medical devices, catheter systems, and diagnostic tools. The biocompatibility of the materials used ensures patient safety, establishing TG tubes as a crucial component in healthcare technology.

Oil and Gas Sector

In the oil and gas industry, TG tubes are critical for applications involving pipelines and drilling equipment. Their robustness and ability to withstand extreme environmental conditions and high-pressure situations are essential for safe and efficient resource extraction.

Aerospace Engineering

Weight reduction is a primary concern in aerospace engineering. TG tubes provide a lightweight alternative to conventional materials without sacrificing strength. Their incorporation into aircraft components not only contributes to enhanced fuel efficiency but also improves overall aircraft performance.

Advantages of TG Tubes

The benefits of TG tubes extend far beyond their robust structural characteristics. Their growing popularity across various industries can be attributed to several key advantages:

Exceptional Durability

TG tubes are engineered to endure harsh environments, including extreme temperatures, high pressure, and corrosive conditions. This resilience not only ensures a longer service life but also minimizes maintenance expenses and reduces the frequency of replacements.

Versatile Applications

One of the standout features of TG tubes is their versatility. They can be tailored to fit diverse applications, ranging from construction and automotive to medical fields, ensuring that specific project requirements are effectively met.

Cost Efficiency

Although the initial costs for TG tubes might be higher compared to other materials, their longevity and minimal maintenance requirements often lead to significant cost savings over time. This makes them a smart investment for many projects.

Lightweight Construction

The lightweight design of TG tubes simplifies transportation and installation processes, resulting in considerable labor savings. This advantage is particularly significant in industries like construction and aerospace, where managing weight is crucial for operational efficiency.

Enhanced Operational Performance

TG tubes contribute to improved performance in various systems. Their design facilitates smooth fluid flow in pipelines and provides robust structural support in buildings, ultimately enhancing overall efficiency and safety.

Innovations in TG Tubes

As technological advancements continue, so too does the evolution of TG tubes. Below are some of the most recent innovations that are influencing the future of these products:

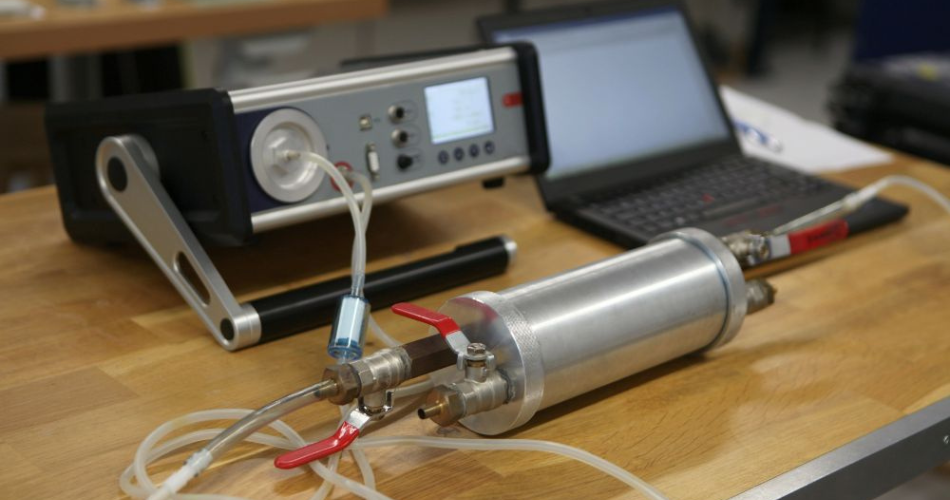

Smart Technology Integration

The advent of smart TG tubes, which incorporate sensors, is transforming their utility across sectors. These smart tubes can deliver real-time data regarding pressure, temperature, and structural integrity, allowing for proactive maintenance and heightened safety in critical environments.

Focus on Sustainability

In response to the increasing importance of eco-friendliness, manufacturers are investigating the use of sustainable materials in the production of TG tubes. By utilizing recycled materials and implementing innovative manufacturing processes, they aim to lessen the environmental footprint of these products.

Advanced Protective Coatings

Recent developments in protective coatings for TG tubes enhance their resistance to corrosion and wear, significantly prolonging their lifespan, especially in demanding applications such as oil and gas extraction.

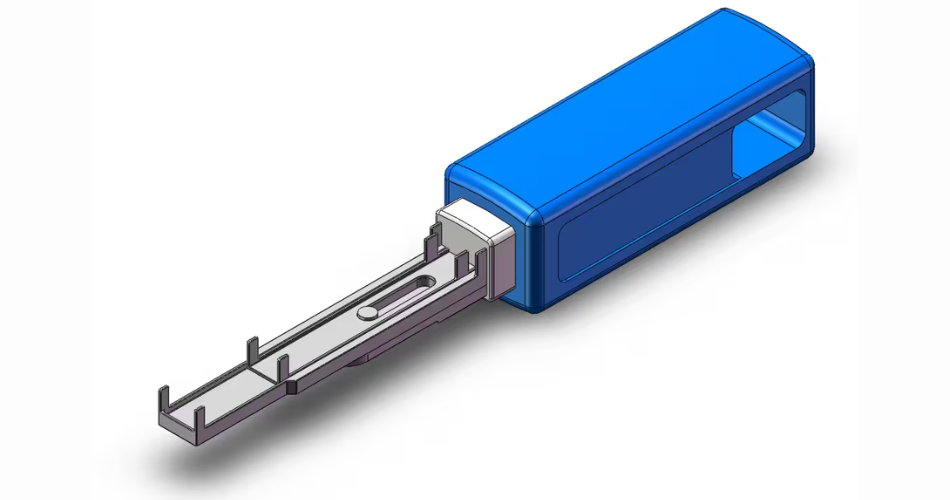

3D Printing Capabilities

The rise of 3D printing technology is revolutionizing how TG tubes are produced. This method enables rapid prototyping and tailored designs, allowing manufacturers to meet specific customer demands without the extended lead times associated with traditional manufacturing.

Customized Solutions

The growing demand for tailored designs in TG tubes is being met by manufacturers offering bespoke solutions that cater to unique applications. This customization ensures that clients receive products specifically aligned with their requirements.

Challenges and Considerations in Using TG Tubes

While TG tubes offer numerous benefits, several challenges and considerations should be addressed to ensure their effective application in various sectors:

Material Selection

Selecting the appropriate material for TG tubes is paramount. Each application has specific requirements concerning attributes such as strength, flexibility, and environmental resistance. Failing to choose the right material can lead to performance failures, resulting in expensive repairs and operational interruptions.

Cost Implications

Although TG tubes can provide long-term cost savings, the initial expenditure might deter some organizations from adoption. Businesses must carefully assess the upfront investment relative to the potential for future savings to make informed decisions.

Regulatory Compliance

For industries like healthcare and aerospace, adherence to strict regulatory standards is critical. TG tube manufacturers must ensure their products comply with all relevant certifications and regulations to guarantee safety and effectiveness.

Technological Integration

As industries evolve toward more intelligent solutions, integrating new technologies with existing systems can be a complex task. Organizations may need to invest in staff training and infrastructure improvements to fully harness the advantages of advanced TG tube technologies.

Supply Chain Management

Like many sectors, the supply chain for TG tubes can face disruptions due to global events, resulting in delays and higher costs. Companies should develop resilient supply chain strategies to navigate these challenges effectively.

Future Outlook for TG Tubes

The future of TG tubes is bright, with continuous innovations and an increasing demand across various industries. As sectors prioritize efficiency, sustainability, and high performance, TG tubes are set to play a crucial role in meeting these needs.

Growing Demand in Emerging Markets

As developing nations focus on infrastructure growth and industrial expansion, the demand for TG tubes is anticipated to rise. This trend presents manufacturers with opportunities to extend their market reach and explore new regions.

Advancements in Technology

Ongoing technological advancements are expected to spur further innovation in the realm of TG tubes. The future may see the introduction of advanced materials and smart solutions, enhancing both performance and safety.

Emphasis on Sustainability

With a rising focus on environmental stewardship, the market for sustainable TG tubes is likely to grow. Manufacturers that prioritize eco-friendly materials and production processes will be well-positioned to satisfy this emerging demand.

Collaborative Efforts

As industries increasingly seek comprehensive solutions, partnerships between manufacturers, technology providers, and end-users are expected to become more prevalent. These collaborations will drive innovation and lead to products tailored to specific industry challenges.

Market Growth Prospects

The overall market for TG tubes is projected to experience steady growth, fueled by ongoing infrastructure developments, new technological innovations, and the growing complexity of applications across various sectors.

Conclusion

In summary, TG tubes are essential in a wide range of industries, offering a unique blend of durability, versatility, and cost-effectiveness. Their applications span fields such as construction, automotive, healthcare, and aerospace, making them indispensable in contemporary engineering and manufacturing. As technological advancements continue, the innovations surrounding TG tubes will enhance their capabilities, ensuring their relevance in meeting industry demands.

Professionals in relevant fields must understand the advantages and challenges associated with TG tubes. Staying updated on the latest trends and developments will enable businesses to leverage these advantages, ultimately leading to more efficient and sustainable operations. Whether considering the integration of TG tubes into a specific project or simply seeking to expand your knowledge about this innovative product, the insights provided here serve as a valuable guide. Embrace the potential of TG tubes and discover how they can enhance your projects and processes.

FAQs about TG Tubes

1. What are TG tubes?

TG tubes, also known as tubular goods, are cylindrical structures made from materials like steel, aluminum, or plastic. They are designed for various applications due to their strength, lightweight nature, and ability to facilitate fluid flow.

2. What industries use TG tubes?

TG tubes are utilized in a wide range of industries, including construction, automotive, healthcare, oil and gas, and aerospace. Their versatility allows them to meet specific needs in each sector.

3. What are the key benefits of using TG tubes?

The primary benefits of TG tubes include exceptional durability, versatile applications, cost efficiency, lightweight construction, and enhanced operational performance, making them suitable for various demanding environments.

4. How are TG tubes manufactured?

The manufacturing process of TG tubes involves selecting high-quality materials, followed by precise engineering and fabrication techniques to ensure they meet stringent performance standards.

5. What are the common applications of TG tubes in construction?

In construction, TG tubes are often used for structural frameworks, scaffolding, and support systems due to their lightweight design and strength, which facilitate easier handling and installation.

6. Are TG tubes safe for medical use?

Yes, TG tubes are often made from biocompatible materials, making them safe for medical applications, including catheters and diagnostic tools.

7. What innovations are shaping the future of TG tubes?

Recent innovations in TG tubes include smart technology integration with sensors for real-time data monitoring, sustainable manufacturing practices, advanced protective coatings, and 3D printing capabilities for customized solutions.

8. What challenges are associated with using TG tubes?

Challenges include selecting the appropriate material for specific applications, managing initial costs, ensuring regulatory compliance, and integrating new technologies into existing systems.

9. How do TG tubes contribute to sustainability?

Manufacturers are increasingly focusing on using recycled materials and eco-friendly production processes in TG tube manufacturing, which reduces environmental impact and aligns with growing sustainability efforts across industries.

10. What is the future outlook for TG tubes?

The market for TG tubes is expected to grow due to rising demand in emerging markets, ongoing technological advancements, and an emphasis on sustainability. Collaborations among industry players will likely drive further innovation.

Stay in the know with the latest news and updates on MumbaiBreaking